Case Study: University of Portland’s Dundon Berchtold Hall Entries

Oct 30, 2019

Written By versatile

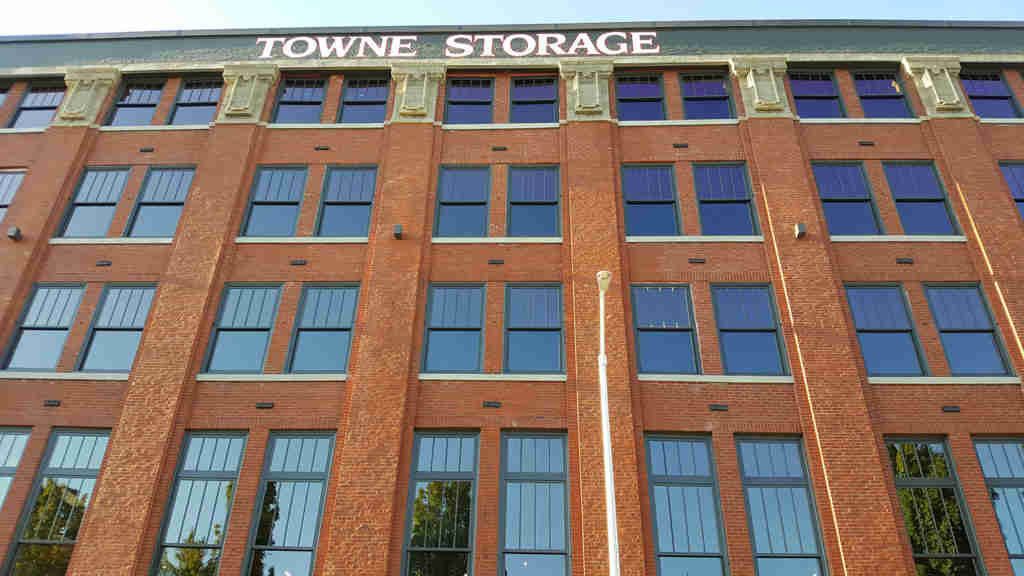

Dundon-Berchtold Hall is the first new academic hall that University of Portland has opened on campus in over two decades, and Versatile Wood Products was thrilled to be a part of its completion.

The intention behind the design was to create a space that was aesthetically similar to the historic buildings that are on campus and in the vicinity. A classic, traditional look was the goal, with stylistic references to the Collegiate Gothic style commonly seen in prestigious East coast universities.Versatile designed and built six door pairs with sidelites and Gothic arched-top transoms, as well as two single doors with traditional rectangular transoms. This classic aesthetic calls for quarter sawn white oak. This species is historic, durable, and beautiful, but it takes a skillful eye to select layouts from this type of wood. Pieces were selected for harmony in both grain and color. The look of the finished product is determined when we first handle the rough lumber in the mill.

But the challenges didn’t end with lumber selection. Since Classic architectural elements are defined by their dimensionality, grand formal entrances like these call for multiple layers of trim. Large, chunky millwork profiles add depth and drama to the design and visually support the heavy detailed doors. Adding a Gothic arch to this formula made this a technical feat that we addressed with both traditional and modern methods. Accuracy was paramount in order to match up all of the curved pieces precisely, and for that task we looked to our CNC operator.

Before the pieces could be cut out, the wood blanks had to be assembled. Keeping in mind the color and grain harmony mentioned above, we also had to consider how the grain was going to be revealed on the round pieces. Quarter sawn grain patterns are revealed when wood is cut at a specific angle.

Our mill foreman had to consider how the grain would be revealed as the shapes emerged from the blanks, and with a curved piece, this is a more challenging process. Additionally, with the heavy wood and long expanses, the joints had to be robust and strong. This required compound miter glue-ups, where the face of the glue-up is angled to the shape of the final curved piece, while the meeting joints are also angled to increase glue surface. All of this planning and consideration is necessary before it ever hits the CNC platen. Once we were ready to start cutting the shapes, the CNC operator must determine the best plan of attack for the cuts—not only the direction, but the depth and speed of each pass. To lose a piece due to tear-out after all that work can be heartbreaking. The CNC is a high-tech tool but requires as much skill and thoughtfulness as any other woodworking instrument.

Versatile Wood Products partnered with Fortis Construction and Soderstrom Architects to bring this project to life. Our high-quality design and expert craftsmanship created these exceptional entries, which will grace the entrance of Dundon-Berchtold Hall for many decades to come.

FOLLOW OUR BLOG

RECENT POSTS

©2023 Versatile Wood Products

2303 N. Randolph Ave., Portland, OR 97227

Mon – Fri 7:30 am – 4:00 pm

website by

Snow B. Designs

2303 N. Randolph Ave., Portland, OR 97227 | 503-238-6403 quotes@versatilewp.com | Mon – Fri 7:30 am – 4:00 pm | Privacy | We're members of these organizations:

Restore Oregon , Architectural Heritage Center, FSC®, The American Institute of Architects (AIA), Home Builders Association, National Kitchen + Bath Association, National Association of the Remodeling Industry

All Rights Reserved | Versatile Wood Products | Website by Snow B. Designs